Powerful magnetic filtration of system debris with an 800 micron sieve to remove non-magnetic debris. Circulating debris in water heating systems can cause wear and premature failure of pumps, valves and heat exchangers.

Instructions, dosing information and safety data sheets for our chemical, filter and scale protection products.

Learn more

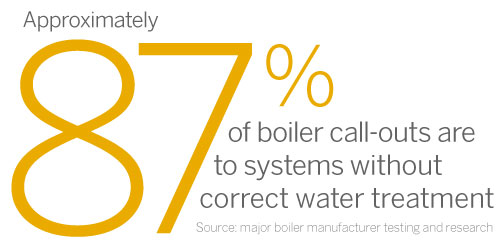

It’s basic chemistry – when water comes into contact with metals, rust happens.

Learn more

Our first water softener, the high-efficiency, non-electric and compact Sumo unit, is coming to the UK market! Having successfully sold the Sumo in France, Sumo is now available to UK customers, giving access to the benefits and advantages that the Sumo’s technology offers. Installers have an...

As water treatment specialists, we at Sentinel are delighted to bring our first water softener, the high-efficiency, non-electric and compact Sumo unit, to the UK market. Having successfully sold the Sumo in France, we have now made the Sumo available to UK customers, to benefit from the...

A RECENT STUDY CARRIED OUT BY THE HHIC HAS REVEALED THAT ALMOST HALF OF HOMEOWNERS DO NOT HAVE THEIR BOILER SERVICED REGULARLY, AND APPROXIMATELY 3 MILLION UK HOUSEHOLDS MAY NEVER HAVE HAD THEIR BOILER SERVICED. SO, HOW DO WE CHANGE THE HOMEOWNER VIEW OF BOILERS AND THE HEATING SYSTEM, AND THEIR...

This items explores and summarises the Part L changes. We have highlighted to top five changes which have been made and how they will affect you. In short, BS7593 (the ‘Code of practice for the preparation, commissioning and maintenance of domestic central heating and cooling water systems’),...

As a member of HHIC, Sentinel have worked closely with the HHIC on development of the important new app from Benchmark, which is now live! The move aims to digitise the Benchmark scheme, making boiler care easier for everyone involved. Full installation, servicing, and commissioning data...

ULTRA-COMPACT, ULTRA-CONVENIENT – VORTEX250 DELIVERS! Sentinel are delighted to announce the expansion of our successful Eliminator Vortex system filter range, by releasing our first ultra-compact magnetic system filter, the Eliminator Vortex250. Having listened to market feedback, we have...

Sentinel is a company with a clear goal: we offer water treatment products and services that provide the best lifetime protection for heating and hot water systems. Originally launched in the UK by Grace Dearborn in 1988 and subsequently a subsidiary of the leading multinational General Electric, Sentinel has operated independently since 2005, expanding its international reach and range of innovative solutions. As of 2021, Sentinel is owned by Aalberts N.V., and sits in the hydronic flow control cluster.