Clean dirty heating systems, protect against future issues and maintain system performance with Sentinel Rapid-Dose®.

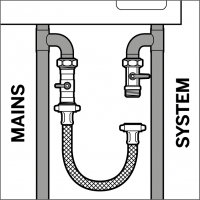

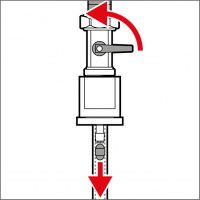

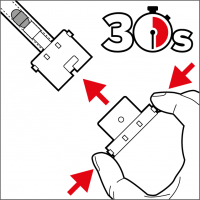

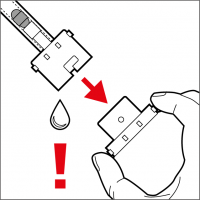

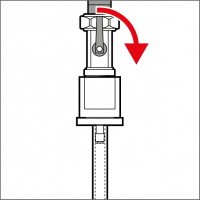

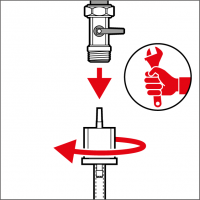

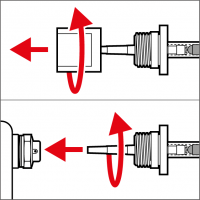

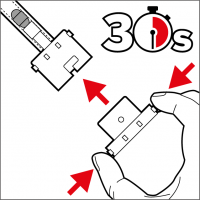

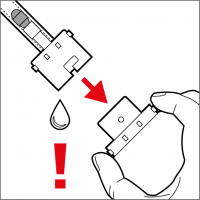

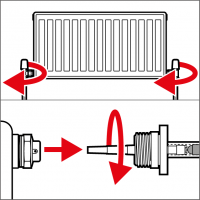

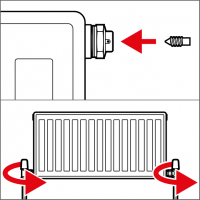

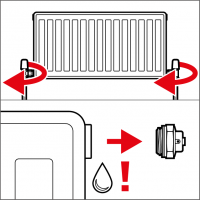

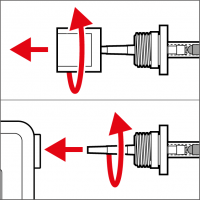

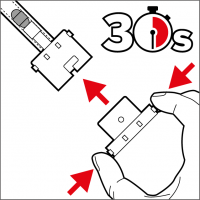

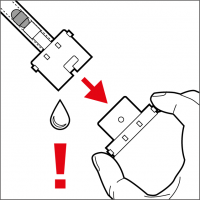

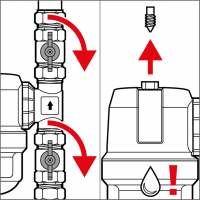

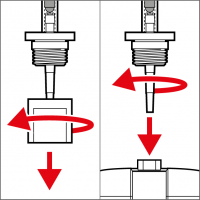

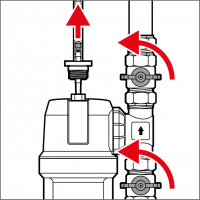

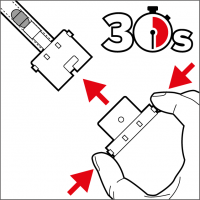

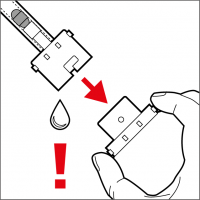

Our dosing adaptor allows for four simple dosing methods. The adaptor also features our visible bullet, which prevents water from escaping the system and provides visible confirmation of dosing.

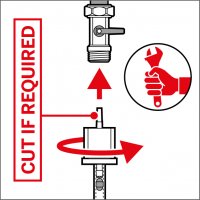

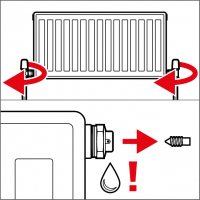

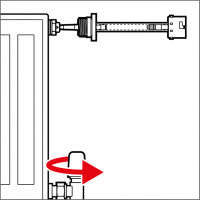

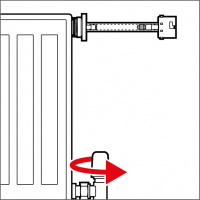

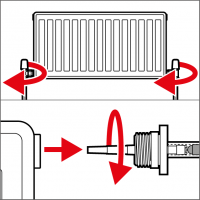

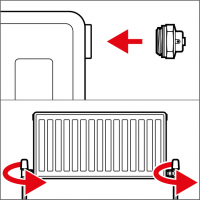

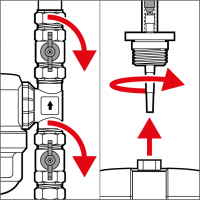

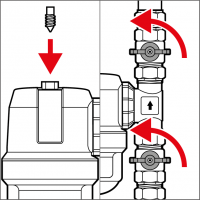

If a filling loop is fitted and accessible use Method 1 to dose via the filling loop stop valve, if not use Method 2 or 3 to dose via the radiator. Alternatively, use Method 4 to dose via the bleed valve if a Sentinel Eliminator or Eliminator TotalGuard filter is fitted. It is also possible to dose via an Eliminator Nano, but only if complete isolation is achievable.

*It is only necessary to release system pressure when it is above 2.3 bar.

Sentinel is a company with a clear goal: we offer water treatment products and services that provide the best lifetime protection for heating and hot water systems. Originally launched in the UK by Grace Dearborn in 1988 and subsequently a subsidiary of the leading multinational General Electric, Sentinel has operated independently since 2005, expanding its international reach and range of innovative solutions. As of 2021, Sentinel is owned by Aalberts N.V., and sits in the hydronic flow control cluster.